Engineered for Engineers

"We got invited to one the biggest civil engineer projects in North America, the Oroville Dam episode, to help them collect data that they otherwise just couldn't get accurately. It's definitely a big feather in our cap."

Stephen Perry, PEng

Civil Engineer

Brunswick Engineering& Consulting Inc.

Opening New Frontiers

One concept that comes up over and over is around how UAVs shouldn’t be thought of as a solution that’s going to solve every problem on a project, but instead as tools that create options and expand alternatives. Engineering companies have been at the forefront piloting UAVs exploring the potential of our technology’s versatility. The ability to reliably capture, accurate data with our aircraft systems, has expanded and created opportunities in the engineering sector.

Critical Decision Accuracy

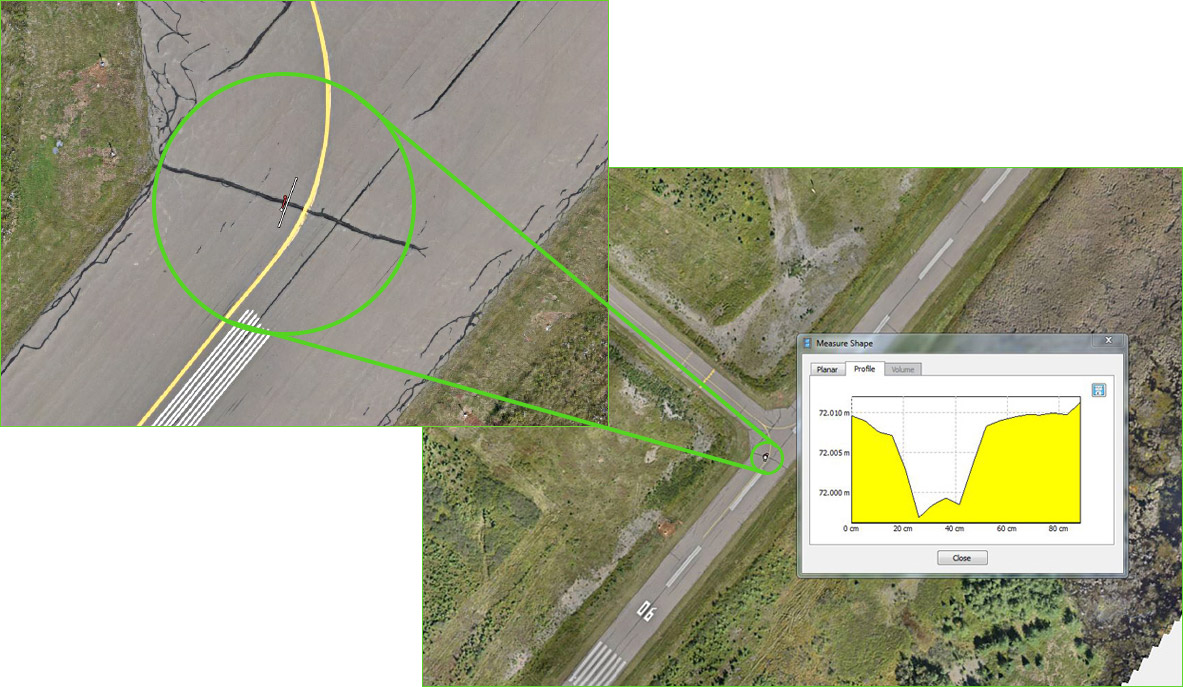

mm level profiles of a runway crack captured by a Surveyor 630 UAV flying 100m above the runway

A high level of relative, as well as absolute accuracy is required by our clients to support the critical determinations for their projects. We are pleased to learn that in “real world” operations, our clients are capable of surveying greater than 120 acres per flight with 1.5 cm X and Y and 3cm Z precision when operating their Infinite Jib™ UAS in conjunction with ground control points. The final survey will be as accurate as the accuracy of the measurements done for the ground control points.

Having one of our reliable UAVs to produce accurate measurements, will save you time and move your project one step closer to meeting scheduled deadlines, reducing costs and increasing profitability.

Dangerous Site Deployment

Workers inspect damage of Oroville Dam emergency spillway

Major industries continue to work diligently addressing the complex issues of health, safety and environment (HSE), yet it remains one of the top priorities in local, regional and global organizations. Improved health and safety standards help companies become more effective to finish projects on time and improve their business profile with customers and clients. When there is a need to capture information of a remote or hazardous area, companies are increasingly turning to our UAV technology to reduce risks and prevent job site accidents.

According to the Occupational, Safety and Health Association estimates, in North American alone, workplace injuries and illnesses cost employers billions per week in worker’s compensation without factoring in the additional costs that result from lost productivity, staffing replacements and repairs to damaged equipment. Our systems are being used to perform inspections in a safer manner, identify potential hazards before they become costly and dangerous; thus improving the safety at industrial worksites.

Infinite Jib™ aircraft perform real-time, remote inspections and reduce the need for your crews to be in potentially dangerous areas.

Save Time – Increase Profitability

What quickly became obvious to our clients was that repeatedly, they realized significant time- savings using our equipment. Our aircraft systems efficiently and safely accessed structures in remote location for inspection and investigation. Using our real time video feeds, your inspection crews will have the ability to immediately focus their efforts on explicit areas of interest.

Inspection and investigation of difficult to access structures

"The Jib" Advantage

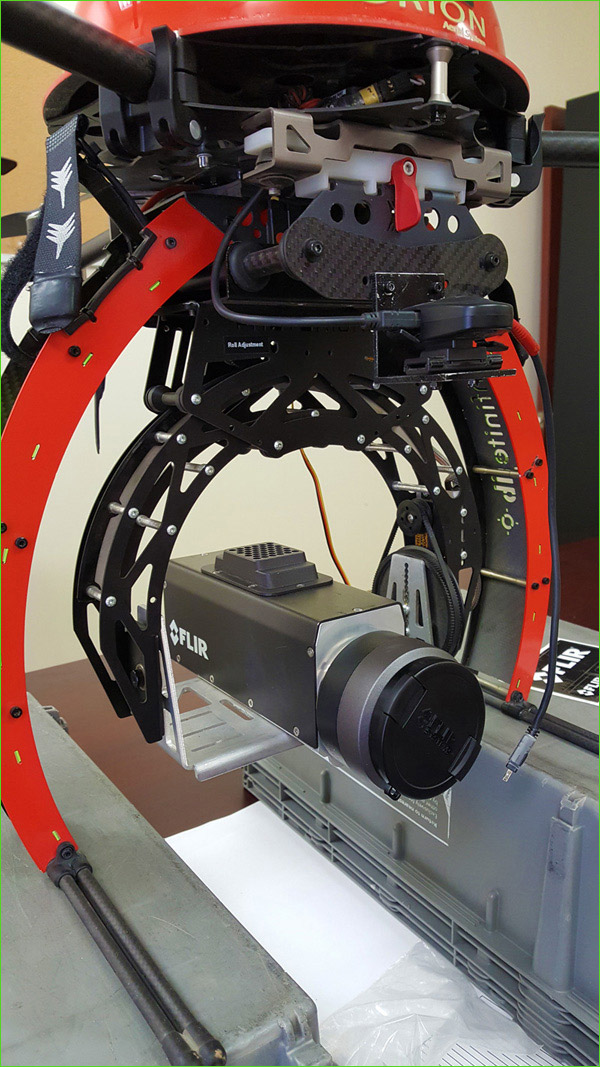

Over the years, our clients have actively explored how to expand opportunities for UAV inspections. Requirements emerged to operate larger DSLR cameras, Optical Gas Imaging (OGI) and in some cases combine sensor payloads. Due to the robust design of our UAVs, we have been able to modify and upgrade existing systems to satisfy our client’s needs. When faced with a unique, specific requirement, our highly trained technicians not only to help determine the feasibility but develop a design strategy for the custom build.

At Infinite Jib™ we are constantly developing new solutions to enhance safety features, increase productivity, performance and maintain compliance with evolving regulations. It is our mandate to develop the means whereby new technologies can be retrofitted onto existing Infinite Jib™ aircraft systems to add more value and sustainability to your investment.

Orion 700 adapted to operate with

FLIR 300 gas detection sensor

Recommended UAV Systems:

• Surveyor 630 Photogrammetry UAS Solution

• Orion 700 Thermal / Photogrammetry UAS Solution

• Nexus 800 LiDAR / Photogrammetry UAS Solution

Recommended UAV Systems:

• Surveyor 630 Photogrammetry UAS Solution

• Orion 700 Thermal / Photogrammetry UAS Solution

• Nexus 800 LiDAR / Photogrammetry UAS Solution

INTELLIGENT REMOTE SENSING INDUSTRIAL UAV SYSTEMS